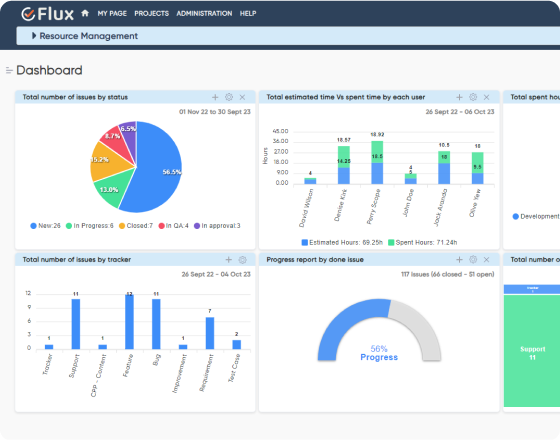

Redmineflux plugins have been a game-changer for our Redmine setup. The enhanced features like advanced time tracking, custom workflows, and improved reporting have significantly boosted our productivity. The integration was seamless, and the support team was fantastic. Highly recommend these plugins to any Redmine user!

Alex Tucker

Project Manager, Newyork

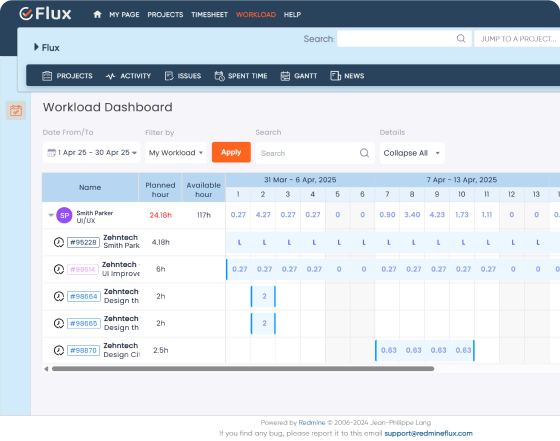

Getting all of my business data organized in one place is all I wanted. With Redmineflux, I can filter data and simplify my agile operations.

Alfred Fleischer

Project Manager

Redmineflux themes have completely transformed the look and feel of our Redmine instance. We were looking for a way to make our Redmine more visually appealing and user-friendly, and these themes delivered on both fronts. The customization options are fantastic, allowing us to tailor the design to our company’s branding.

Chen Jun Hao

Project Manager, Singapore

The Redmineflux Timesheet plugin has made it so much easier for our team to track their time. The ability to easily log time for multiple tasks at once and bulk edit or delete entries is a huge time saver.

Emily Garcia

Project Lead,Spain

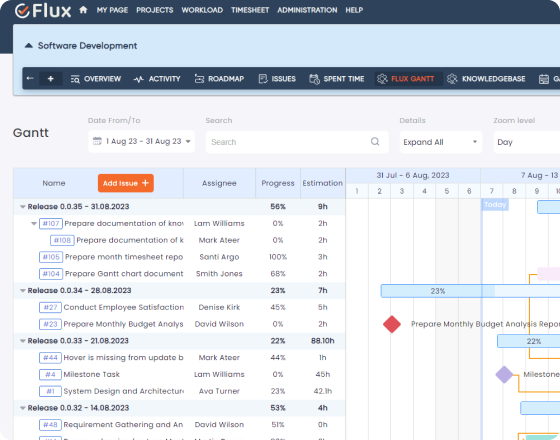

Redmineflux Gantt Chart improved visibility and Efficiency, it provides a clear view of tasks, improves communication, & streamlines workflows for faster project completion.

Maria Rodriguez

Team Lead,Rochester,U.S.

Redmineflux themes are not just about aesthetics; they’re designed with user experience in mind. The improved navigation and clarity have streamlined our workflows significantly. The support team was also incredibly helpful in assisting us with customization.

Highly recommend!”

Marlena Sievers

CEO, Brazil

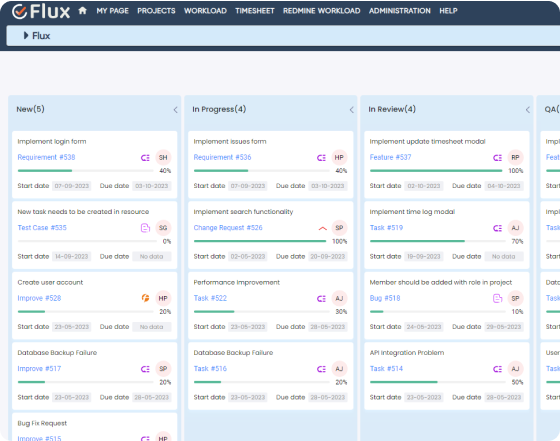

Redmineflux has an easy-to-use interface & is easily customizable. It helps active coordination and focuses project resources in one direction.

Safra Barra

Project Manager

The self-hosted version of Redmineflux has transformed our enterprise project management. The customization options and reliable performance have greatly improved our workflows. The support team is responsive, ensuring our needs are met. Highly recommended for organization looking to streamline project management.

Samantha Lone

Project Manager, Moscow, Russia